How to Create and Launch a Sunscreen in Australia as a Beauty Founder

a step by step guide, using L'ORIENT's sunscreen as a case study

It’s 11 PM on Sunday and after a few long days of solo parenting whilst my husband is away working in rural NSW in charge of a hospital, I am writing this. I don’t envy him at all, I do not miss the chaos and never ending work the hospital brings, but equally, raising a baby alone for stretches is no small feat.

To paint the rather unglamorous scene, my daughter is asleep and attached to my breast, flutter feeding away, my wrists heavily pronated and uncomfortably flexed to their capacity, and I am typing slowly, like a child learning to type, key by key, with my laptop propped up on a pillow as I lie rather uncomfortably on my side (becoming a mum means I am on her schedule and when she’s awake I have no time or opportunity to write or do any work).

Yet I wanted to write to escape the hours of Teletubbies watched today that delighted little Penelope (and numbed my neurons), distracting her from her two little bottom teeth currently making their way into the world. More importantly to fulfil a commitment I made to write an article a week released on a Sunday. This is a day late which marginally upsets me however, I think I am allowed a little grace this week, and this one is a goodie.

Whether you’re a consumer curious about the fabled ‘hardest place in the world to make a sunscreen’ or a founder wanting to explore making your own. I didn’t have this play by play and as previously elucidated, people seem to gate-keep knowledge in the industry here. So here it is plain and simple for you. Enjoy!

SUNSCREEN: THE UNIFYING BEAUTY ESSENTIAL

If there’s one universal skincare product that everyone should own, it’s sunscreen. Which makes it a crucial, replenishable product in demand no matter your background demographic (great for repeat sales, steady revenue streams at predictable cadences and customer loyalty if you play your cards right).

The revenue for the sun-care products industry ( sun block, after-sun products and self tanning products) in 2023 was 97.3 million. If this industry grows at the same rate as the broader cosmetic industry (3.4% annualised over five years), it can be extrapolated that the ‘Sunscreen and Other Skincare Product Manufacturing industry’ will be worth approximately $115 million in 2028 and approximately $136 million in 2033.

Within Australia, high rates (the highest globally in fact) of skin cancer and high UV levels means high market demand. Gone are the days where sun safety was viewed as overkill and unsexy, where people lathered on baby oil and attended solariums to work on their tan. Add on increasing concerns about photodamage and ageing along with pigmentary concerns and conditions like rosacea seeing sunscreen as a cornerstone of prevention and management, it also means a tightly regulated, competitive market.

I MADE A TGA APPROVED SUNSCREEN THAT NEVER LAUNCHED

When I first ideated L’ORIENT in 2021, our goal was to come to market with a sunscreen as our first product for these reasons. In the case of my target consumer, pigmentation care cannot be effective without the diligent use of sunscreen. At that time, players like Ultraviolette and Naked Sundays had emerged dominating the category with their refreshing, innovative takes packaged in enticing pumps and bottles, new textures, finishes and application ways, cutting through a traditionally stale industry. White cast has universally been an issue for skin of colour consumers, not to mention oily greasy finishes. At that time, I knew nothing about anything re launching this type of product, naive and unaware of the hoops to jump through.

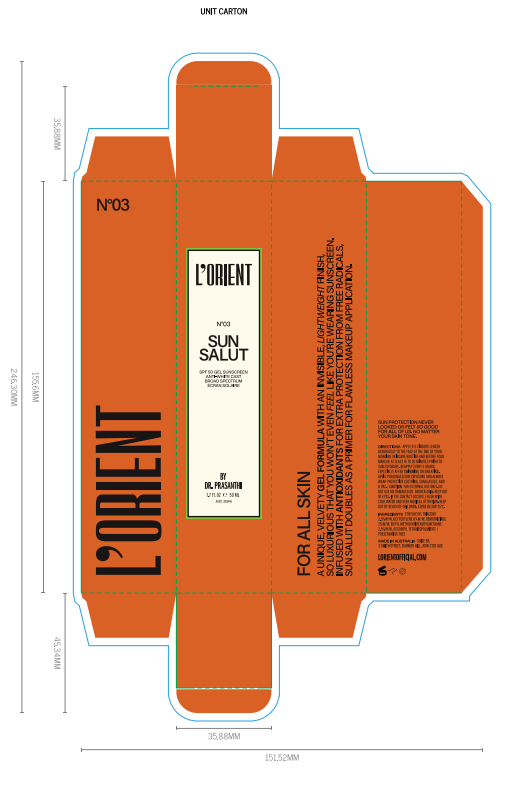

Many don’t actually know that we did complete and finish a clear, matte, gel broad spectrum sunscreen that functioned as a perfect primer base (like the Benefit pore blurring one) that was TGA approved. It was non greasy, blurring, and made makeup look supreme. However, prior to mass manufacturing, I had raised concerns the sample was feeling gritty, like grains of sand on my face (only to be gaslighted by the turnkey provider management that this wasn’t the case). Testing after lengthy back and forths revealed one of our filters had precipitated (despite having passed all testing). Devastated (and furious), we decided to abandon the endeavour despite reassurances from our turnkey provider the issue could be fixed (as multiple attempts were given and each time, continued to precipitate and fail).

The market had moved immensely,. A clear sunscreen was no longer innovative or fresh with the launch of Airyday’s Clear Sunscreen and The Quick Flick following a similar suite. Not to mention the ever looming launch of Supergoop with their famous Unseen Sunscreen entering the market with an already wide fan base and brand recognition. Perhaps this was a painful blessing in disguise.

It’s a shame, as everyone who tried our sunscreen before we got our shotty samples loved it. Begged for more in fact. I’ve reconciled with that time lost (and explains why I have been building this brand yet to launch for so long as we had to pivot, and pivot we did). I share this post in the hope that if you are someone thinking of launching into this category, there is more clarity around the steps involved and the financial outlay required. So you won’t be surprised in the way I was. Here are some key things to note if you decide to launch a sunscreen.

Step 1: Understand Regulatory Requirements

Get intimate with the Therapeutic Goods Administration (TGA) Guidelines

In Australia, sunscreens are regulated by the Therapeutic Goods Administration (TGA) as either therapeutic goods (which sunscreens are classified as) or cosmetic products. This is dependent on their claims and SPF level. Products with SPF 15 or higher and therapeutic claims (e.g., “reduces risk of skin cancer”) must be listed on the Australian Register of Therapeutic Goods (ARTG) which means being subject to their testing standards. Primary sunscreens are “Products that are used primarily for protection from UV radiation”. Then there are secondary sunscreens, “Products with a primary purpose other than sun protection, but which also contain sunscreening agents and are not excluded from therapeutic goods legislation”.Many secondary sunscreen products, such as cosmetic sunscreens (makeup or tinted products with an spf of 4-50), are not considered to be therapeutic goods (if no therapeutic claims are made) and are ‘excluded’ from therapeutic goods legislation but equally cannot be listed or labelled as a sunscreen.

There are 3 pillars to general standards when creating a therapeutic goods listed sunscreen.

Formulation Testing: Ensuring compliance with Australian Standards (AS/NZS 2604:2021).

Safety and Efficacy Data: Clinical evidence supporting SPF claims and water resistance.

Labeling Requirements: Follow strict guidelines on SPF, UVA/UVB protection, water resistance, and directions for use.

Step 2: Develop Your Formulation

Find a contract manufacturer of a TGA approved manufacturing facility (with an in house development team) or an independent cosmetic chemist or lab experienced in sunscreen formulation. The manufacturer will need a certificate like below (this was from our proposed sunscreen manufacturer):

I go into ways to find this in my previous post. Here is a list from a quick google search + some labs I know.

https://www.wildchild.com.au/products/sunscreen-manufacturers/

https://baxterlaboratories.com/

https://deltalabs.com.au/

https://skinterest.com.au/services/formulation/

https://www.logikalhealth.com/

Choose Your Ingredients

You can either come to your team with specific requirements e.g. many people want a completely mineral sunscreen, which eliminates and organic filter use (aka chemical sunscreens), specific SPF goals, format, texture, claims etc, or let your development lead take the reins. Your formula will need to be compliant with the TGA’s approved ingredients at the percentages allowed for both active and inactive parts of the formula (where active refers to the filters protecting against UV radiation and inactive everything else that goes in).

Active Ingredients: Zinc oxide and titanium dioxide vs chemical filters like avobenzone, Tinosorb S and octocrylene. A combination of actives will be needed usually, especially if a chemical sunscreen,to achieve a broad spectrum label (protecting adequately against both UVA and UVB).

Supporting Ingredients: Hydrators, antioxidants, and skin-soothing agents to enhance product appeal e.g. niacinamide, kakadu plum extract, hyaluronic acid.

Compliance: Ensure all ingredients are approved by the TGA and the Australian Industrial Chemicals Introduction Scheme (AICIS).

Once you have a formula you are happy with, it’s time for all the testing.

There are 2 types of tests: SPF and stability testing.

SPF testing has to follow the most recent TGA standards (at the time we followed the 2019 protocol but this has now been updated) and assess on real subjects the minimum erythema dose in response to artificial UV light with your product on subjects skin. It took roughly 2 months to return. At the end you receive a report on the SPF of your product.

STEP 3: TESTING

SPF 30/50/50+ WHAT’S THE DIFFERENCE

Usually people are aiming for SPF 30,50 or 50+. SPF 50 can be labelled as high protection and SPF 50+ irrespective of how high the actual number is will be allowed to say very high protection. Our actual SPF was 54.1 (deemed ‘high protection’). To be “very high” it needs to be 60+.

HOW TO ACHIEVE A BROAD SPECTRUM LABEL

To be listed as broad spectrum (that is protecting adequately against UVA and UVB), guidelines vary regionally, Australia follows the ISO 24443 standard.

For example: the criterion for broad-spectrum formulations for EU says the UVA protection factor (the potential to prevent persistent pigment darkening) must be at least 1/3 of the SPF (solar protection factor).

In the US, the 2019 proposed rule is changing requirements for designation of broad-spectrum coverage, “A UVA I/UV ratio of 0.7 or higher, indicating that the product provides a minimum measure of UVA I radiation absorbance relative to total UV radiation (i.e., UVB + UVA) absorbance, in addition satisfying to the 370 nm critical wavelength requirement”.

In Aus, to pass the broad spectrum performance test as per the ISO, no more than 10% of the UV radiation may pass through the sunscreen layer or solution at any wavelength across the UVA range. That is equivalent to saying that the sunscreen must block at least 90% of the radiation at each UVA wavelength.

The product will also need to be stability tested to ensure a shelf life between 6-36 months. 4 months accelerated stability provides a 2 year shelf life, 6 months accelerated a 3 year shelf life.

THIS S**T AIN’T CHEAP

One of the biggest barriers to launching a sunscreen is cost due to all the testing required and higher minimum order quantities. I found a summary of what we paid in a working excel spreadsheet I had. It is really important you understand these costs are coming. Our turnkey provider sprung these on us once we had approved our formula (they had no idea what was going on). Had we known, we may have opted to launch this at another time. We were stuck and thankfully had the funds to front this but I just think about if we had been a client who couldn’t. Hopefully this transparency gives you an idea of what you need to have in the bank if you’re formulating something from scratch. These prices have most definitely increased with inflation (this was December of 2022).

Here is a snapshot of our SPF report.

Here is a snapshot of our stability test.

Additional testing incurs additional costs for additional claims

Water resistance: In the water resistance test, the sunscreen is applied to the volunteers’ skin and they immerse the area concerned in a pool of water for a period of time. Then after being dried in air, the skin is irradiated and the SPF is determined as in the previous method. The water resistance rating (in minutes or hours) that can be declared on the product label is the total time the test areas of skin were immersed.

Dermatological Testing: Confirm safety for sensitive skin. Bit of a misleading test in my humble opinion as it alludes to a dermatologist approving or testing the formula but many brands do this as it does lend authority.

Step 4: Packaging and Labelling requirements

Packaging

Depending on whether or not you have secondary packaging (a box for your sunscreen), you may need to wait until your product has been TGA approved and an AUSTL number provided before you can proceed with production to meet labelling requirements. Stability needs to occur in your final packaging so select this wisely.

Labelling

There are also rules around text sizing you will need to comply with, and the artwork for your vessels is submitted along with reports in your TGA application. Other things like active filters and quantities, specific allowed claims, mandatory warning (around reapplication etc) are all listed in this hyperlink above. Familiarise yourself to get this right with your graphic designer in one shot.

Step 5: Apply for TGA approval

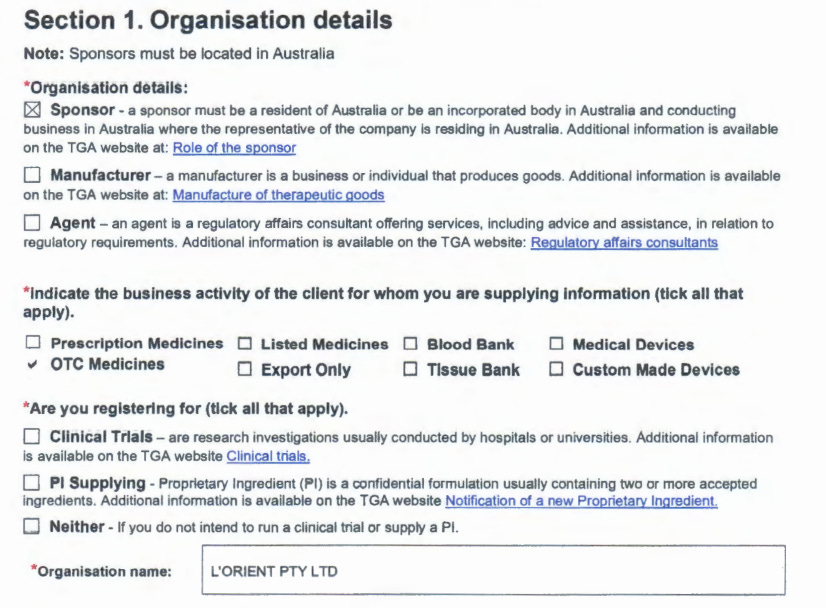

Finally, months, perhaps years later, you are ready to submit your product for TGA approval. You will either have 2 options here: apply yourself, and create a TGA Business Service account, or use a regulator (independent or business). The former lists yourself solely as the ‘sponsor’ and if going the latter part, you also need to approve an ‘agent’ acting on your behalf.

In our case, we used a regulatory consultant working in Sydney at Engel Hellyer and Partners. You pay an hourly rate for any services and application. Our consultant, Gloria, submitted all our documents of TGA approved manufacturing facility, report paperwork (SPF and stability) and artworks on our behalf. TGA approval can be a notoriously variable process. In our case, our sunscreen was approved within a fortnight with no issues. But i have heard of this process taking months for others. So factor this into your planning.

Step 6: Manufacturing

Now you have your approval, the AUSTL number provided can be printed onto your packaging and manufacturing can begin. However, you likely may have been waiting for approval to come through prior to ordering your raw materials. This has another lead time added onto it, anywhere from 6 weeks to months (in our case proposed lead time of the raw materials was 20 weeks, which in retrospect was far too long. Our turnkey provider had not placed the order, despite us asking. This meant we were needing to wait another 5 months for materials to even arrive).

When raw materials arrive, they are subject to further testing at the manufacturing facility, incurring another cost. This includes ID testing and HPLC, real shelf life stability and lab testing of raw materials, costing upwards of 12,000 AUD. Another surprise cost sprung on us but important to factor in to your financial planning and supply chain logistics.

Is it all worth it? Final thoughts.

Launching a custom sunscreen in Australia is a long journey that requires meticulous planning, compliance, innovation and a reasonable chunk of finances. By understanding the regulatory landscape, addressing unmet consumer needs, and building a strong unique brand, your start-up can carve out a space despite this competitive market. Sunscreen remains such a personal thing, no two people enjoy the same sunscreen and as a doctor who has used a LOT of sunscreen, I can still safely say I haven’t found ‘the one’ my holy grail just yet. Whilst we have had to abandon this particular formula, we still hold the TGA approval. It is my hope to create a sunscreen down the line, once a little bit of the market settles. My dream is to actually partner with someone and create a patented and superior filter for protecting against long wave UVA (also known as UVA 1) and visible light, wavelengths that are particularly concerning for people dealing with hyperpigmentation. So far there is only one company providing peak protection in this wavelength, La Roche Posay, with their UV Mune 400 Mexoryl filter variations. Protecting Australian skin and especially darker skin tones, while building a sustainable and inclusive brand is not just a business opportunity to me, it’s a meaningful mission that genuinely improves consumer skin health and cancer prevention. If you have any questions for me feel free to DM me, or leave me a comment. Happy concocting! And remember, slip slop slap seek and slide.